| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | OEM |

| Model Number : | cnc milling aluminum parts |

| Certification : | Rohs, ISO |

| Price : | $1 |

| Payment Terms : | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability : | 1000pcs/month |

| Delivery Time : | 10-15working days |

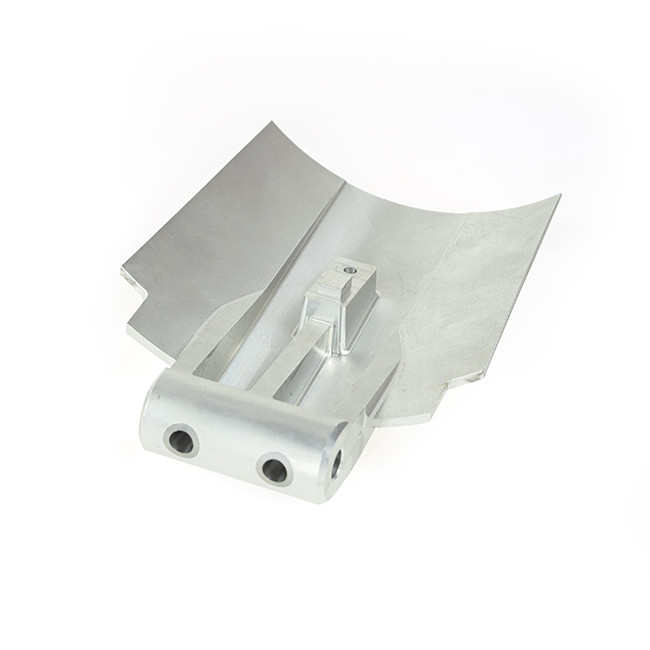

CNC 7075 Aluminum Bearing Finishing 5-Axis Milling Service Custom Wholesale

| Support Custom CNC Machining Parts Of Most Materials | |

| Quotation | According to your drawing(size, material, processing content, etc) |

| Tolerance丨Surface Roughness | +/-0.02 - 0.02mm(Customize available)丨Ra0.2 - Ra3.2(Customize available) |

| Materials Avaiable | Such as aluminum, copper, stainless steel, iron, PE, PVC, ABS, etc. |

| Surface Treatment | Polishing, general, hard, color oxidation, surface chamfering, tempering, etc. |

| Processing | CNC turning, milling, drilling, auto lathe, tapping, bushing, surface treatment, anodized, etc. |

| Drawing Formats | CAD/PDF/DWG/DXF/DXW/IGES/STEP etc. |

| Our Advantages | 1.) 24 hours online service & quickly quote/delivery. 2.) 100% QC quality inspection before delivery, can provide quality inspection form. 3.) 10+ years of experience in the CNC machining area and have a senior design team to offer perfect modification suggestions. |

What milling cutter is best for milling aluminum alloy parts?

What kind of milling cutter is used for milling aluminum alloy is a

very important issue. There are two reasons: one is that the

milling cutter has a greater impact on milling performance, and the

other is that the choice of milling cutter will directly affect the

processing cost. According to the above reasons, it is particularly

important for how to choose a milling cutter. Common types of

milling cutters. This is a relatively common problem, because

milling aluminum alloys has some unique characteristics, so

different milling cutters are used to deal with them. There are

several types of commonly used milling cutters, such as ordinary

milling cutters, conical milling cutters, flat bottom milling

cutters and V-shaped milling cutters. Depending on the shape and

size of the part you are working with, it is important to select

the proper milling cutter. For example, if you are machining round

parts, a conical milling cutter would be more appropriate. Flat

bottom milling cutters can be used to machine flat surfaces, while

V-shaped milling cutters can help you with small parts like

grooves, grooves, grooves. In conclusion, choosing the correct

milling cutter is crucial to produce a beautiful and high-quality

product. Therefore, be sure to carefully consider the part you are

dealing with and its condition before purchasing. How to choose a

milling cutter when milling aluminum alloy? The first step: Find

the latest milling cutter manufacturer information. You can search

online or ask a friend for a recommendation. Step 2: Select the

type of milling cutter according to the material, thickness, size,

processing direction and other requirements of the material you

need to process. Commonly used milling cutters are flat milling

cutters, cube milling cutters, cylindrical milling cutters,

multi-layer milling cutters and ball end milling cutters. Step 3:

After selecting the milling cutter, communicate with the

manufacturer to confirm the specification size and quantity.

More CNC Milled Aluminum Parts:

|